Foccci

Disclaimer: This Page is still work in progress! Any information written here is a draft only and should be handled as such. Contributions more then welcome. If you have questions please ask them in the discussion section of the page or in the OpenInvert Forum.

This page is about FOCCCI. FOCCCI is an open source CCS Charge Controller started by Uhi and developed by the OpenInverter Community.

Here you will find documentation on the Hardware, where to get it (or how to build it yourself), News regarding the development and many more great things.

On Foccci runs the reference software CCS32Clara (also referred to as Clara).

Foccci for sale on OpenInverter Shop

Foccci in the OpenInverter Forum.

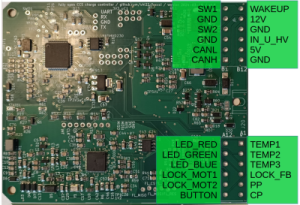

Pin description

External connector ("Deutsch Header")

Starting version 4.5b the pins were reshuffled to allow one wiring loom going to the charge port and one to the car side. Changed pins are bold.

| Short name | Pin up to 4.5a | Pin from 4.5b | Description |

|---|---|---|---|

| TEMP1 | A1 | A1 | Power pin temperature sensor. It is pulled up to 3.3V with 10k and the sensor must pull down to GND. Sensor characteristics are configurable in software |

| TEMP2 | A2 | A2 | As above |

| TEMP3 | A3 | A3 | As Above |

| LOCKFB | A4 | A4 | Feedback signal from connector lock. Pulled up to 3.3V with 10k, so feedback must pull down to GND. Thresholds configurable in software |

| IN_U_HV | A5 | B10 | Analog input 0 to 5V, with pull-down-resistor. Can be used to measure the charge port voltage, using a converter board, e.g. the "muehlpower board" |

| CP | A6 | A6 | CP (Control Pilot) pin from charge port |

| SW2(_LS) | A7 | B4 | Output for charge port contactor 2. Low side switch until Foccci 4.4, high side switch starting 4.5

Controls one of the contactors to make the connection between the HV battery and the vehicle inlet. The output can drive inductive load without additional circuits. It will clamp the turn-off voltage to ~40V. The driver has protection against shortcut and thermal overload. The output can be configured to be just digital on/off, and can also be configured to use PWM. BUT: In Foccci versions 4.2 and 4.3 (maybe more) the output driver is only capable of slow PWM, which is hearable and may cause trouble with the contactors. So it is recommended to NOT use the PWM feature, and instead use contactors which do not require economizing or use external economizers. In case you want the PWM nevertheless, you need a external freewheeling diode. Starting Foccci 4.5 PWM is working as intended at 18 kHz. It is a high side output starting v4.5, so the other side of the contactor must be connected to GND. Before v4.5 it is a low side output so the other side must be connected to 12V |

| LOCK_MOT2 | A8 | A8 | Motor driver output for charge port lock servo |

| LOCK_MOT1 | A9 | A9 | |

| PP | A10 | A5 | PP (Proximity Pilot) pin from charge port. If you want Foccci to wake up when an unpowered charge cord is plugged in you must close JP3 to pin 1 (towards R7). There mustn't be a pull-down resistor in the charge port in this case as that would permanently keep Foccci awake |

| 5V | A11 | B11 | 5V, 500mA e.g. for supplying voltage sense board. This is an OUTPUT of Foccci. Do not apply an external voltage source here. Foccci contains a step-down-converter from the 12V supply to this 5V output. |

| GND | A12 | B12 | |

| CANH | B1 | B1 | CAN communication |

| CANL | B2 | B2 | |

| n.c. | B3 | Unused pins were assigned GND in 4.5b | |

| n.c. | B4 | ||

| GND | B5 | B5, B3 | |

| SW1(_LS) | B6 | B6 | Output for the charge port contactor 1. See description of SW2(_LS). |

| WAKEUP | B7 | B7 | Wakeup bus. Momentarily (or constantly) applying 12V wakes up the board. In the other direction Foccci can wake up (or supply with up to 1A) other devices via a 12V high side switch |

| 12V | B8 | B8 | Supply voltage, always on. 9 to 24V are fine. |

| LED_RED | B9 | A12 | Status LEDs |

| LED_GREEN | B10 | A11 | |

| LED_BLUE | B11 | A10 | |

| BUTTON | B12 | A7 | Wakes up Foccci or stops an ongoing charging session |

Internal connectors

| short name | description |

|---|---|

| UART TX | Provides logging information, 921600 Baud. See also https://github.com/uhi22/ccs32clara/blob/main/doc/clara_user_manual.md#serial-logging |

| UART RX | Not used |

| SWCLK | for flashing with STLINK |

| SWDIO | for flashing with STLINK |

Wakeup

For charging it is particularly interesting to wake up Foccci itself and necessary subsystems [1] when plugging in a charge cord. To allow for this, Foccci has various wakeup sources and also can wake up other devices. For wakeup to work, Foccci must be permanently supplied with 12V (it will draw no current when asleep).

Here are the sources:

- Wakeup pin - bidirectional - level triggered (12V)

- Button - level triggered (GND)

- PP - optional via solder bridge - level triggered

- CP - Edge triggered

So the first 3 inputs will force the Foccci on. It can't turn itself off as long as that wakeup source is active. The last input will only trigger when transitioning from invalid to valid PWM and then Foccci can decide how long to stay awake. All modes always work regardless of software settings - except PP wakeup which can be turned off in hardware (JP3).

The wakeup output on the other hand is software-defined. Clara offers the following options

- Level - as long as the Foccci doesn't decide to turn off, we keep Wakeup on as well

- Pulse - When Foccci boots generate a 1s wakeup pulse

- LevelOnValidCp - As long as CP is pulsing we keep wakeup on

- PulseOnValidCp - Whenever we transition from non-pulsing to pulsing CP we generate a 1s pulse

- LevelOnValidPp - As long as PP is valid keep wakeup on

The output can supply about 1A and 12V. When running loads larger than that (e.g. a pump) use a relay to amplify the current capability.

It depends on your vehicle architecture how you organize the wakeup. Here are some examples:

Basic wakeup

wakeup via PP enabled, WakeupPinFunc=LevelOnValidPp

- Foccci turns on as soon as even a non-powered charging cable is plugged in

- Wakeup signal is turned on

- BMS, VCU etc. is turned on (directly powered from wakeup as it can supply about 1A)

- VCU can detect via the level of the wakeup signal that a cable is plugged in and inhibit drive

- When charging cable is unplugged (as in PP lost), Wakeup is turned off and the VCU can allow driving

- If we wanted to report e.g. welded charge port relays Foccci would have to keep itself running until the car is started in drive mode again. Then something can be displayed on the instrument cluster. Of course this will time out eventually. Should be fine as you at least have to pull away from the rapid charger after charging.

- When charging is paused all ECUs stay on and consume 12V power (or HV power via DC/DC)

Advanced Wakeup

wakeup via PP disabled, WakeupPinFunc=PulseOnValidCp. Here we have a bidirectional wakeup bus. Any ECU connected to it can send or receive wakeup events and the individual ECUs can decide whether they are needed for a particular task or not.

- Foccci turns on as soon as CP PWM starts. So either a cable is being plugged in or is already plugged in and now wants to charge

- It then turns on the wakeup output for 1s and wakes up all other ECUs

- The relevant ECUs will detect that we want to charge and stay on, the other ones turn off

- If we turn on ignition the VCU is already on and in charge mode and can inhibit drive

- If charging is paused (i.e. cable plugged in but no CP PWM) and we turn on ignition the VCU wakes up the Foccci and queries PP status. If something is plugged in drive is inhbited

- If Foccci detects an error e.g. welded relays, it stores that error to flash. When woken up by the VCU it report its non-zero error code

- When charging is paused, ALL ECUs can turn off and no 12V power is consumed. When CP comes back, the cycle restarts

The second approach is more versatile but it also means all devices need to support this method.

So I think there can be an intermediate approach:

Semi-advanced wakeup

Here we only have a wakeup bus between VCU and Foccci. All other devices are powered up by other means, like VCU controlled relays. Wakeup via PP is disabled, WakeupPinFunc=LevelOnValidCp

- Foccci turns on as soon as CP PWM starts. So either a cable is being plugged in or is already plugged in and now wants to charge

- It then turns on the wakeup output this waking up the VCU

- The VCU determines via CAN message from Foccci whether we want to AC or DC charge and turns on needed components. Components needed in both cases that have low power consumption (e.g. BMS) can also be driven from the wakeup signal directly

- If we turn on ignition the VCU is already on and in charge mode and can inhibit drive

- If charging is paused (i.e. cable plugged in but no CP PWM) and we turn on ignition the VCU wakes up the Foccci and queries PP status. If something is plugged in drive is inhbited

- If Foccci detects an error e.g. welded relays, it stores that error to flash. When woken up by the VCU it report its non-zero error code

- When charging is paused, ALL ECUs will turn off and no 12V power is consumed. When CP comes back, the cycle restarts

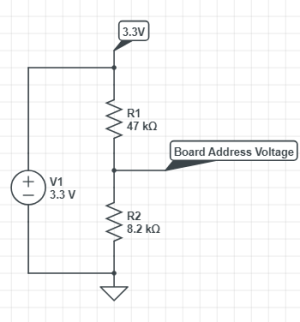

Hardware detection

To allow software to reliably detect which version hardware it runs on, in HW version 4.1 a version indication resistor was added. As opposed to some other boards that run at 5.3V, the voltage here is 3.3V.

| Variant | R1 | R2 | voltage | ADC | -3% | +3% |

|---|---|---|---|---|---|---|

| - | 47 | 2,7 | 0,179 | 222 | 216 | 229 |

| - | 47 | 3,3 | 0,217 | 269 | 261 | 277 |

| - | 47 | 3,9 | 0,253 | 314 | 304 | 323 |

| - | 47 | 4,7 | 0,300 | 372 | 361 | 383 |

| - | 47 | 5,1 | 0,323 | 401 | 389 | 413 |

| - | 47 | 5,6 | 0,351 | 436 | 423 | 449 |

| - | 47 | 6,8 | 0,417 | 518 | 502 | 533 |

| - | 47 | 7,5 | 0,454 | 564 | 547 | 580 |

| 4.0 with economizer | 47 | 8,2 | 0,490 | 608 | 590 | 627 |

| - | 47 | 9,1 | 0,535 | 664 | 644 | 684 |

| 4.2 | 47 | 10 | 0,579 | 718 | 697 | 740 |

| 4.3 | 47 | 12 | 0,671 | 833 | 808 | 858 |

| 4.4 | 47 | 15 | 0,798 | 991 | 961 | 1020 |

| 4.5 | 47 | 18 | 0,914 | 1134 | 1100 | 1168 |

| 47 | 22 | 1,052 | 1306 | 1266 | 1345 | |

| 47 | 27 | 1,204 | 1494 | 1449 | 1539 | |

| 47 | 33 | 1,361 | 1689 | 1639 | 1740 | |

| 47 | 39 | 1,497 | 1857 | 1801 | 1913 | |

| 47 | 47 | 1,650 | 2048 | 1986 | 2109 | |

| 47 | 56 | 1,794 | 2226 | 2160 | 2293 |