VW Hybrid Battery Packs

pre charge relayInformation on reusing VW Golf/Passat GTE hybrid battery Packs.

Specification Overview

Passat GTE

The 9.9 KWH Passat GTE battery pack contains 96S 28AH Samsung cells arranged in to 4 modules of 24S with a liquid cooled heatsink down the middle.

Note: Battery capacity has been increased to 13kwhr in circa 2019 (assumed to be 37ah cells).

Golf GTE

The Golf GTE battery pack has a plastic top cover, containing 8.7 KWH Panasonic cells arranged in to 4 modules of 24S with a liquid cooled heatsink down the middle.

Disassembly

I Can Not understate the importance of Insulation when dealing With High Voltages, Both of your tools and yourself of course! Also ensuring that we do everything to prevent a Shor Circuit.

All Metal tools were covered in Tape And/Or Heat Shrink so that in the event of a drop there would not be a dangerous short circuit, and also as an added layer of insulation from the battery to myself!

I only ever toughed the HV contacts when I absolutely had to, no point taking chances!

Useful/Tools used:

- Torx & Socket Drive Set (insulated with shrink wrap/tape)

- Electric Screwdriver

- Magnet on a stick (Covered in tape of course)

- Insulation Tape & Duct Tape

- Gloves … I used nitrile gloves, Electrician’s gloves & some garden gloves so I didn’t tear the electrical gloves.

- Electrical screwdrivers & a normal screwdrivers covered in insulation tape.

- Voltmeter

- Insulated shoes

- Nylon straps the battery came tied to the pallet.

- Emergency help on hand in case of electrocution (including gloves for them & I attached one of the nylon straps to myself so I could be pulled away)

- Work in the dry obviously

After Undoing all of the torx bolt on the top the cover can be removed … look at those precision straps to hold the modules down.

At this point after prodding about underneath the foam and looking down the sides I need access to the bottom to unbolt the modules, find that un-loved screwdriver (covered in paint in my case on top of my daughter’s rabbit hutch) and use gentle persuasion to remove the rubber plugs to get access to the torx bolts and remove them. Be very careful this thing is damn heavy you don’t wan this to land on your toes or any part of your body

Now back to the top side … remove all the foam, disconnect all of the cables you can (I could not remove the module bms plugs). Happily my module sat at 355 volts (88.8v per module) so not too low at about 3.7v per cell!

I then started tackling all of the bolts holding down the modules in the middle, however then came the ones that were under the Contactor box.

The scary bit where I disconnected the HV connections from the Contactor box thing, immediately covering with insulation tape, first negative, positive, then I tackled the mid pack connection (not shown in this photo). Then I removed all of the connections from the contactor box to allow it the removed to allow access to the torx bolts obstructed by it.

Now back to the top side … remove all the foam, disconnect all of the cables you can (I could not remove the module bms plugs). Happily my module sat at 355 volts (88.8v per module) so not too low at about 3.7v per cell!

I then started tackling all of the bolts holding down the modules in the middle, however then came the ones that were under the Contactor box.

The scary bit where I disconnected the HV connections from the Contactor box thing, immediately covering with insulation tape, first negative, positive, then I tackled the mid pack connection (not shown in this photo). Then I removed all of the connections from the contactor box to allow it the removed to allow access to the torx bolts obstructed by it.

Golf GTE

The same safety advice as above applies, these packs are over 350V DC, this can be LEATHAL. DO NOT BE COMPLACENT.

The Golf GTE pack is a heafty aluminium box with a plastic lid. The lid is covered in a very thin aluminium layer. I found it quite a task to break in, there's a lot of silicone around the perimeter. I used a mixture of breaking the cover and levering it up as much as possible and cutting the silicone.

Under the plastic is a blanket covering the modules. The goodies are underneath.

The next task I did was to remove the main leads from the battery pack to the contactor box. These just lift up to disconnect, they are pretty well insulated but take no chances, they are direct to the modules, always live. With both of these removed you can begin un bolting the contactor box.

BMS

The BMS slaves on the modules can be re-used using SimpBMS running on a Teensy Microcontroller.

https://github.com/Tom-evnut/SimpBMS

https://github.com/Tom-evnut/VW-bms

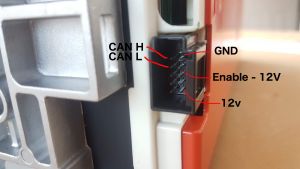

Each half-module will need connecting to the can bus for SimpBMS, top right as you are looking at it is pin 1 - GND, move down and skip one pin to 3 - Enable (12V), move down again and skip one to pin 5 - 12v. Top left is pin 6 CAN HIGH, and the one under it is pin 7 CAN LOW.

Battery Modules

Passat GTE

The Battery Module weighs 23.4 Kg, (Add module dimensions), There is a BMS connector (TE 1-1670990-1) on both sides of the the module.

|

|

Golf GTE

Each module consists of 2 rows of 12 cells, with a liquid cooling plate between then. Each block of 12 cells is 1086Wh, so each module is 2172Wh.

Roughly 240mm wide, 440mm in length and 150mm in height, each module weights []. One side has a mounting bracket close to the base, the other has one towards the top.

|

|

|---|

Cooling

The Battery Cells are cooled by a liquid cold plate in the middle of the module, the outside diameter of the metal pipe connector is 8.0mm

|

|

Contactors/Pre-Charge

Passat GTE

The Control box contains

- PEC 300A 450VDC fuse

- 2 x Contactors (Data Matrix Code '#3Q0915646B ###100117*288 LS301CRFIFO*=', Non Economiser Type Current Draw 0.556A@12.8V)

- 1 x Pre-Charge Relay (Data Matrix Code '#3Q0915646A ###281116*288 LS301HGC9KB*=')

- 1 x Pre-Charge Resistor (Resistance TBC)

- 1 x Current Shunt (Data Matrix Code:p88970180259, Rating TBC)

- 1 x Contactor Control Board

|

|

|

INSERT

Resistor Pic |

|---|---|---|---|

|

|

|

Reusing with Open Inverter controlling the contactors and relay directly should be as simple as supplying 12v and switching the ground as required.

Golf GTE

The control box contains a

- PEC 250A 450VDC fuse

- 2 x Panasonic AEV14012 M28 contactors https://docs.rs-online.com/6251/0900766b80e1fbed.pdf, yazaki 7283-1020 is the connector

- pre-charge relay and resistor,

- Current shunt.

|

|

|

|---|---|---|

|

Reusing with Open Inverter controlling the contactors and relay directly should be as simple as supplying 12v and switching the ground as required.

The main control board has 2 connectors, one end looks to be high voltage and the other has the external connections and precharge/contactor controls.

| Pin | Function | Wire Colour | Additional |

|---|---|---|---|

| 1 | Connects to battery case | Black | Ring terminal on the end, maybe for isolation test? |

| 2 | Gnd | Black | |

| 3 | N/C | ||

| 4 | CAN H | White | 125ohm resistance between them. IC501 - TJA1042 |

| 5 | CAN L | Black | |

| 6-9 | N/C | ||

| 10 | Red | ||

| 11 | Red | ||

| 12 | White | ||

| 13 | N/C | ||

| 14 | White | ||

| 15-19 | N/C | ||

| 20 | Pre charge relay switched gnd | Black | Q409 is responsible for switching this to ground. |

| 21 | Contactor switched gnd | Black | |

| 22 | Contactor switched gnd | Black | |

| 23 | 12v for precharge relay | Yellow | Isolated from 12v supply |

| 24 | 12v for contactor | Blue | Isolated from 12v supply |

| 25 | 12v for contactor | Red | Isolated from 12v supply |

| 26 | N/C |

Using Multiple Packs

Note: This section is very very rough draft!!and needs a lot more work!

Currently NO Turn Key solutions exist for using more than 1 pack, however .... The items below have NEVER been tested and could only be described as experimental !!

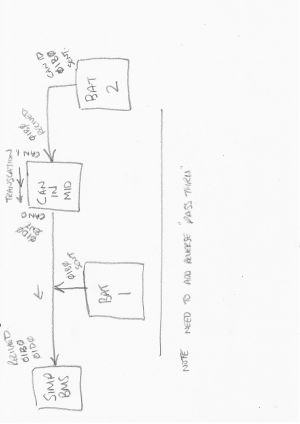

- The next release of SIMP BMS (assuming to be V3) shall use a teensy 4 which will have 3 canbuses however this is in the early stages of development.

- It could be possible to use 2 sets of SIMPBMS however they would exist on 2 separate can buses, this would not to be easy task to implement.

- It could be possible to translate the CAN id's from the second pack by using a can in the middle and still use a single SIMPBMS however this has never been tested.

The can id's outputted from the modules are fixed, the ranges used are from 01B0 to 01CE (432-462).

If these CAN id's were translated (from the second pack) using a can in the middle device to id's to a range like 01D0 to 01EE (464-494) a single SIMPBMS could be used as there is an undocumented code allowing for extended id's within the VW SIMPBMS code.

Sample can id modifying code can be found in colin kidders git hub for the arduino due

https://github.com/collin80/due_can/tree/master/examples/CAN_TrafficModifier

Damian McGuire has created a can in the middle device

https://github.com/damienmaguire/CAN-BUS-Man-In-The-Middle

BMS code showing extended id's

https://github.com/Tom-evnut/VW-bms/blob/master/VWBMSV2/BMSModuleManager.cpp

Rough Draft of CAN ID translation concept, important note the reverse path needs adding.

There is a can id that simp bms sends out (00BA) that wakes up the modules, this needs to be passed through as is.

|

|||